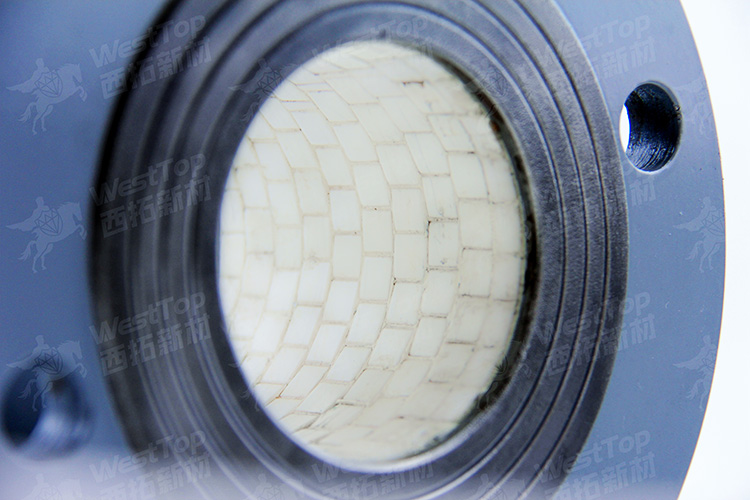

Its inner lining is installed on the steel pipe by combining high-purity corundum ceramics with high-performance adhesives. It is widely used in coal mine, electric power, petroleum, chemical industry, metallurgy, building materials and other fields. High-quality high-purity corundum ceramics are used inside the wear-resistant ceramic pipeline. The surface is smooth and hard, which can effectively resist wear and is not easy to cause damage and fracture. Secondly, wear-resistant ceramic pipes have excellent corrosion resistance. In the chemical environment, high stability, can effectively resist wear and corrosion. This makes the wear-resistant ceramic pipeline very suitable for chemical, metallurgical, electric power and other fields, avoids the high cost maintenance caused by corrosion, and improves the service life and safety stability of the pipeline.

Wear-resistant ceramic pipes also have excellent heat resistance and low temperature resistance, and have high durability in the environment with large temperature difference. The chemical and high thermal properties of alumina ceramic materials are very stable, which can maintain stable physical properties and durability at high and low temperatures. This makes the wear-resistant ceramic pipe can be applied to a variety of harsh working environments, not only to maintain its stability, but also to ensure the continuous stability of the characteristics. In the coal industry, limestone, copper and other minerals are generally used after reprocessing. In the grinding process, the collision and friction between the ore and a large amount of abrasive will lead to serious wear of the pipeline, and the ceramic pipeline is used in the coal mine industry because of its high hardness and strong wear resistance. Replacing traditional pipes with wear-resistant ceramic pipes not only greatly improves work efficiency, but also reduces mechanical consumption and maintenance costs. The foundry industry generally needs to transport high-temperature and high-pressure liquid metal to a specific working area.Under such high temperature and high pressure conditions, the traditional steel pipe is easy to break and deform, while the wear-resistant ceramic pipe can withstand the temperature of 1000 °C and maintain good physical properties. At the same time, the corrosion resistance and compressive strength of wear-resistant ceramic pipes can also improve the production efficiency of the foundry industry and reduce costs. In the chemical industry, because of its unique chemical properties, there will be a violent reaction between different substances, which will produce strong corrosion. The use of wear-resistant ceramic pipes can effectively prevent the corrosion of the inner wall of the pipe and ensure the liquid flow rate and flow rate of the chemical industry. In addition, wear-resistant ceramic pipes can also reduce noise and vibration, ensure a safe and stable working environment, and reduce pollution and personnel damage.

As a high-performance pipeline material, the wear-resistant ceramic pipeline has the advantages of wear resistance, corrosion resistance and impact resistance. It is suitable for high temperature, strong corrosion, high-speed liquid and other strict working environments in various industrial fields. With the continuous progress of material science and technology, the application prospect of wear-resistant ceramic pipes is more and more broad.