Product Briefing

WestTop® SIC high temperature ceramics with its strong oxidation resistance, good wear resistance, high hardness, good thermal stability, high temperature strength, small thermal expansion coefficient, high thermal conductivity and thermal shock resistance and chemical corrosion resistance and other excellent characteristics, in high temperature, thermal shock, corrosion and other harsh environments show its unique advantages.The westtop process makes the ceramic in the liquid phase sintering process supplemented by high temperature isostatic pressing post-treatment to promote the formation of a dense and uniform microstructure. The surface nitriding treatment eliminates the open pores and obtains a ceramic material with high toughness.

WestTop® SIC Due to its low thermal expansion coefficient and high thermal conductivity, the thermal stress of the products during heating and cooling is small, which is the reason why the thermal shock resistance of SIC high temperature ceramics is particularly good.

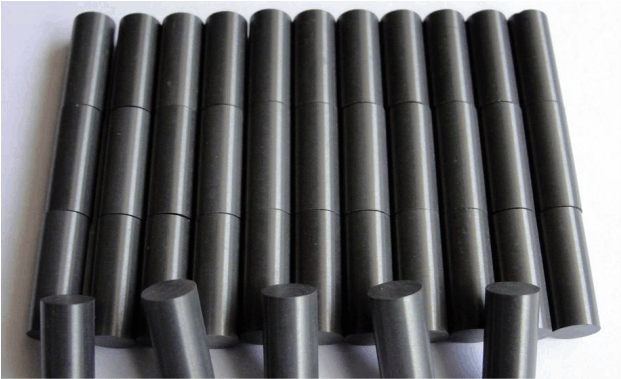

Product Image

SIC high-temperature ceramics

SIC high-temperature ceramics

Performance Characteristics

-

Super high wear resistance : hardness up to 2200HV, wear resistance is more than 30 times the ordinary steel ;

-

Good thermal shock resistance : The thermal expansion coefficient of SIC high temperature ceramics is low and the thermal conductivity is high, so its thermal shock resistance is very good. After heating to 1000 °C, it will not break when it is put into cold water and heated sharply.

-

The high temperature resistance is very good : the strength of SIC high temperature ceramics can be maintained until the high temperature of 1300 °C without decreasing. It is a ceramic with very high high temperature strength at present. It will not melt after heating. It will decompose until 1900 °C, and it will be oxidized at high temperature.

-

Corrosion resistance : In addition to hydrofluoric acid, it does not react with other inorganic acids, corrosion resistance is very strong.

Main Usage

-

In the mechanical industry, it is used as bearing balls, rollers, ball seats, molds, new ceramic tools, pump plungers, sealing materials, etc.

-

In the cement industry, it can be used to make tertiary air valve plate and preheater inner cylinder ;

-

In the chemical industry, used as wear-resistant, corrosion-resistant parts. Such as ball valves, pumps, combustion vaporizers, filters, etc. ;

-

In the metallurgic industry, molds for metal material processing can be made, such as pipe, mandrel, extrusion, wire mold, roll, transfer roll, heating body fixture, thermocouple sleeve, metal heat treatment support, crucible, aluminum liquid pipe, aluminum lining, etc.

-

Aerospace military industry, can be used for armored vehicles, aircraft belly, body armor, rocket nozzle nozzle and other components working at high temperature.