Product Structure

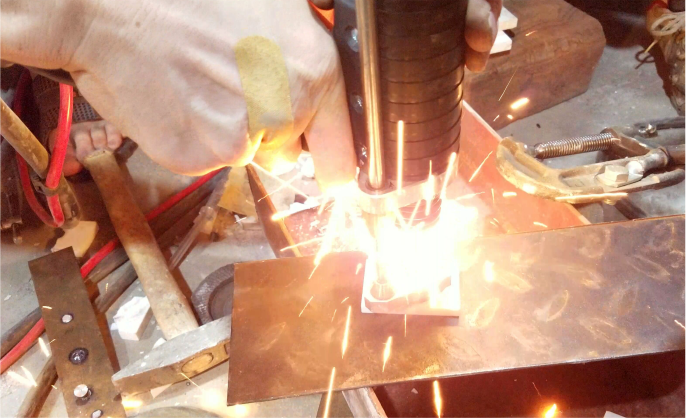

WT-W the welded ceramic is a German technology introduced by WESTTOP to solve the anti-wear of high temperature pneumatic conveying system equipment. Its main structure is to weld the wear-resistant ceramics on the inner wall of the equipment through advanced stud welding process to form a solid anti-wear layer.Optional Material

Ceramics :STC wear-resistant ceramics/ZTA zirconia toughened alumina ceramics

Viscose : WTHV-800

Service Temperature

300℃-800℃

Applicable Medium

Solid powder particles such as pulverized coal, limestone, clinker, cement, etc., slurry such as ash, slag, gypsum, limestone, etc.

Range Of Application

It is suitable for anti-wear of high temperature powder conveying or pulverizing system equipment, such as cement plant waste heat power generation air duct, grate cooler outlet pipe, iron and steel plant sintering machine tail dust collecting air duct, air box air duct and so on.

Regular Size

Thickness 7/10/15mm

Performance Characteristics

Super wear-resisting

Vickers hardness up to 1800, for powder conveying, wear resistance is 20 times that of ordinary carbon steel ;

High temperature resistance, not falling off

Each ceramic has high strength and high wear-resistant bolts to weld it to the bottom steel plate, and the ceramic is not easy to fall off under bad working conditions.

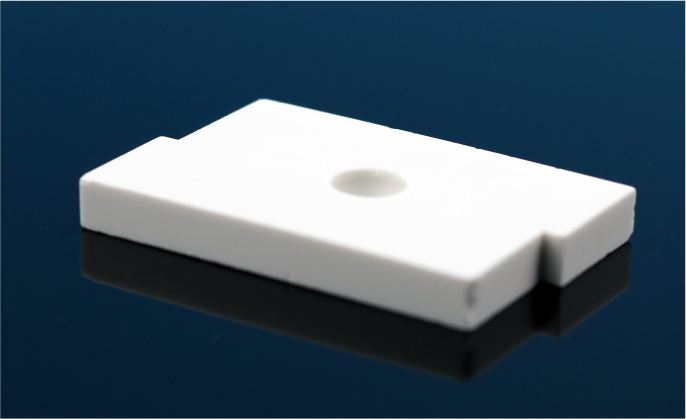

Product Image

Welded wear-resistant ceramic lining (WT-W)

Welded wear-resistant ceramic lining (WT-W)

Welded wear-resistant ceramic lining(WT-W)

Selection Principle Of Wear-resistant Ceramics

| Item | Code | Service Temperature(℃) | Applicable Medium | Material Pellets(mm) | Range Of Application |

|---|---|---|---|---|---|

| Paste Type | WT-P | 300 |

Powder / Slurry |

≤3 |

Pneumatic conveying powder or slurry below 300°C |

| Welded | WT-W | 300-800 |

Powder / Slurry |

≤10 |

Pneumatic conveying of powder or slurry of larger particles below 800 °C |

| Swallow-tailed | WT-S |

≤800 |

Powder / Slurry |

≤200 |

Conveying large particle powder or high-speed rotating equipment below 800 °C |

| Impact resistant type | WT-T |

≤800 |

Particle / slurry |

≤200 |

Bulk material conveying system below 800 °C, especially suitable for the mixture of hard bulk material and powder material |

| Ceramic rubber composite | WT-R |

-50~150 |

Particles / slurry |

≤200 |

Bulk material conveying system below 150 °C, especially suitable for pure soft bulk material conveying, can resist large impact |

| Rapid ceramic repair agent | CRA |

-30~200 |

slurry |

≤10 |

Especially suitable for corrosive slurry conveying equipment lining. |