Project Overview:

The high-speed rotation of the fan causes the two-phase particle airflow containing sludge particle dust to move relative to it, in which the hard two-phase particles collide and move relative to the fan impeller blade, resulting in erosion wear. At this time, if not overhauled in time, it is easy to cause the bearing bush to burn out, or even the entire fan to be damaged. It even causes major accidents such as blade fracture and flying car.

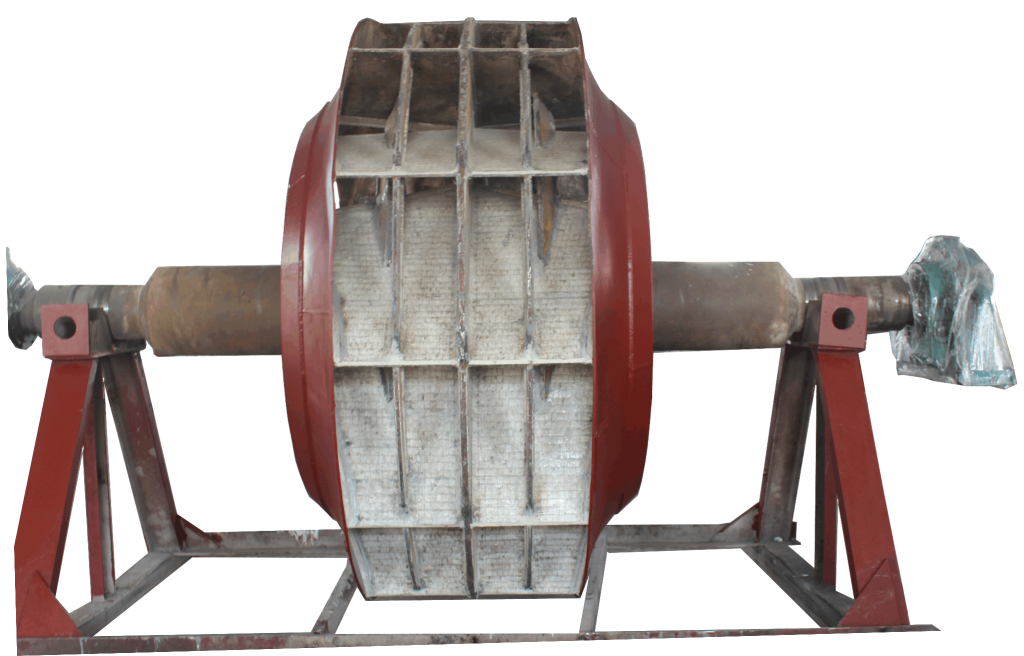

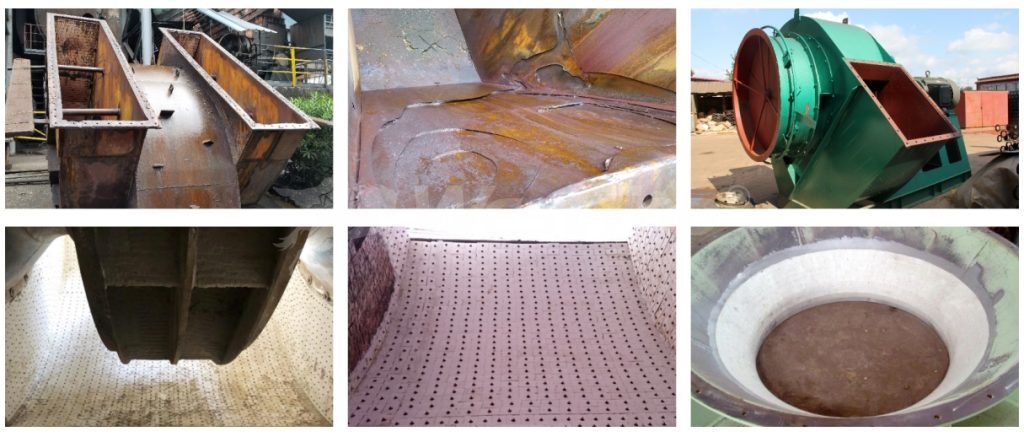

Entrusted by a coking plant of a steel plant, our company carried out anti-wear transformation for its circulating fan impeller. In order to ensure the consistency of the operation status, according to the requirements of the client, this design is based on the on-site collection of data and user requirements for appropriate supplement.

In terms of the performance and basic structure of the whole fan, this design scheme strives to keep consistent with the circulating fan currently used in a coking plant of a steel plant.

Cause analysis of fan wear:

According to the analysis, we believe that the main factors causing the wear of the fan impeller in your factory are the following :

1. ash particle size, ash particle hardness

The materials passing through the fan in a coking plant of a steel plant are mainly coke oven flue gas particles with high hardness. Because of the process decision, it is impossible to improve the wear by changing the particle size and hardness of the ash particles, and can only be solved from other aspects.

2.Velocity and angle of ash particles scouring blade

The fan blade is affected by the two-phase flow of dust in high-speed rotation. The degree of impact wear is related to the centrifugal force of the fluid particles in each part of the blade. The centrifugal force increases with the increase of the radius at the back arc of the blade inlet side. The form and structure of the fan impeller determine the angle of the ash particles scouring the blade, and its speed determines the speed of the scouring. Because the fan impeller cannot be redesigned at this stage, the anti-wear transformation can only be carried out from other aspects.

3.Concentration of dust

The circulating air of the fan in a coking plant of a steel plant carries high concentration of dust. When the fan speed is rated, the centrifugal force is proportional to the dust density in the flue gas and the radius of the particle and the axis. That is, the greater the dust concentration in the flue gas, the more serious the blade wear ; the dust deflects with the airflow under the action of centrifugal force, and the airflow deflects to produce stress concentration. The more times the stress concentration is impacted by the material, the more serious the wear is.

4.Wear resistance of leaves

The impeller is usually used to carry out wear-resistant electrode surfacing treatment in the wear-prone area. The blade surface surfacing has high heat input to the workpiece, high labor intensity, low efficiency, and is easy to cause the deformation of the fan impeller. A large number of micro-cracks will be generated on the metal body, which will bring serious hidden dangers to the safe operation of the impeller. More importantly, compared with the hardness of hard particles, the hardness of the wear-resistant electrode is low, which is not enough to achieve the purpose of wear resistance.

Solution:

We aren’t advocate using pasted ceramic sheets,according to our experience,ceramics treated in this way are easy to fall off,This will cause the fan to be unbalanced and cause severe vibration during operation.

We advocate re-processing a new impeller and installing dovetail-mounted wear-resistant ceramics on the new impeller. The wear-resistant ceramics are fixed by both viscose and dovetail machinery to ensure that the ceramics do not fall off during high-speed operation.

The new impeller can be made by you and shipped to our company for anti-wear treatment, and the drawings can also be sent to us for overall production. After the ceramic is installed, the dynamic balance test is carried out.

(I)Specific measures

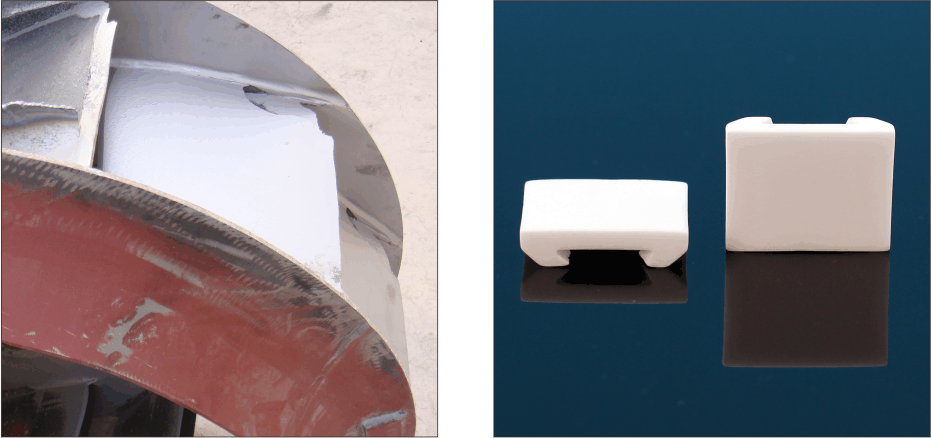

1. Embed dovetail ceramic blocks on the windward side and back of the entire blade;

2. Embed L-shaped ceramic blocks along the blade profile at the joint welds between the rear disc and the front and back of the blade;

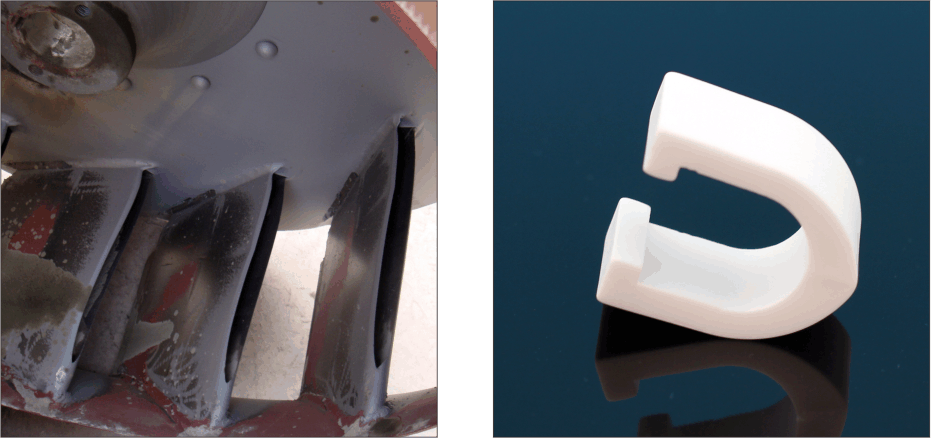

3. The blade air inlet hub is made of U-shaped ceramic;

4. The above ceramics adopt toughening formula; all dovetail ceramics are 4mm thick, all with dovetail grooves, and are reinforced with steel bars; the effective anti-wear surface thickness is 2.5mm (Practice has shown that this thickness is the right choice to extend the life by about 20 times.);

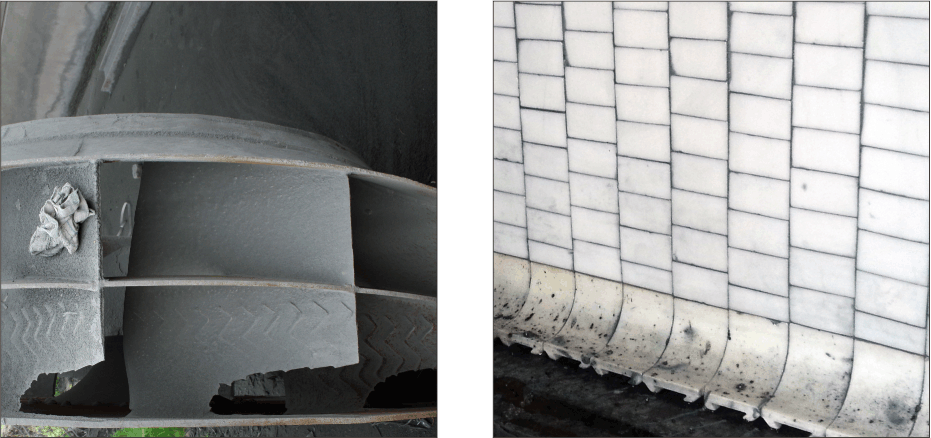

5. The impeller disc is made of 1.5mm ultra-thin ceramic;

6. The dovetail strip is made of special steel to reduce weight as much as possible without reducing strength;

7.The internal welding hole of the dovetail bar is enlarged, which increases the weldable area and makes the dovetail bar welding more firm;

8. The fan housing and air inlet are lined with WT-W type ceramic (on-site installation);

(II) Ceramic performance indicators

|

Project |

Indicators |

|

Alumina Content |

≥70% |

|

Zirconia Content |

≥25% |

|

Density |

≥4.2g/cm3 |

|

Vickers Hardness(HV0.5) |

≥1960 |

|

Compressive Strength |

≥3600 MPa |

|

Fracture toughness KΙC |

≥7.5MPa·m1/2 |

|

Bending Strength |

≥800MPa |

Westtop ZTA ceramics have the characteristics of high green density, uniform density distribution, dense crystal structure, excellent mechanical properties and wear resistance.

(III) Processing cycle

Westtop ZTA ceramics have the characteristics of high green density, uniform density distribution, dense crystal structure, excellent mechanical properties and wear resistance.

Explanation of anti-wear solutions:

1.Protection of the back of the blade

According to our experience, the weld between the blade and the disk is severely worn. Although the back is not as severely worn as the front, once this part is worn, it will pose a safety hazard to the entire impeller and may cause a runaway accident. Therefore, it is recommended to install wear-resistant ceramic protection at the joint between the back of the blade and the disk.

2.About protecting the impeller disk

According to the information we collected from other users, we found that when the wear-resistant ceramic fan impeller has a service life of more than 5 times, although the ceramic installation part is basically not worn and can continue to be used, the previously slightly worn parts such as the impeller disc are seriously worn due to the extension of the overall service life of the fan impeller, resulting in local perforation and forced shutdown for welding. Therefore, we recommend that the impeller disc also be treated with anti-wear.

Performance:

According to the situation learned on site and combined with our experience in anti-wear of similar fans, the service life is several times longer than that of non-wear-resistant fan impellers.