product briefing

WestTop®STT The crystal structure of titanium ceramics is very similar to that of diamond. The type of chemical bond is the same, and the lattice constant is similar. Therefore, it has similar hardness and strength to diamond, which is much higher than that of cemented carbide and ceramics. It is an artificial synthetic material with hardness close to diamond.WestTop®STT Titanium is used as a binder in titanium-gold ceramics. Oxides and nitrides such as Y and Dy, as well as rare earth elements such as Ce, Nd, Gd and Lu, are added to infiltrate into the grains together with aluminum boride and titanium boride, which promotes the densification of polycrystal and improves the strength of the material.

WestTop®STT titanium ceramics not only have many excellent properties of diamond, but also have higher thermal stability and chemical inertness to iron group metals and their alloys. It has higher wear resistance than cemented carbide and ceramics when it is used to process high hardness materials, which can reduce the size deviation or size dispersion in the processing of large parts. The new material that can replace the cemented carbide tool is 8-10 times the comprehensive benefit of the cemented carbide tool material processing.

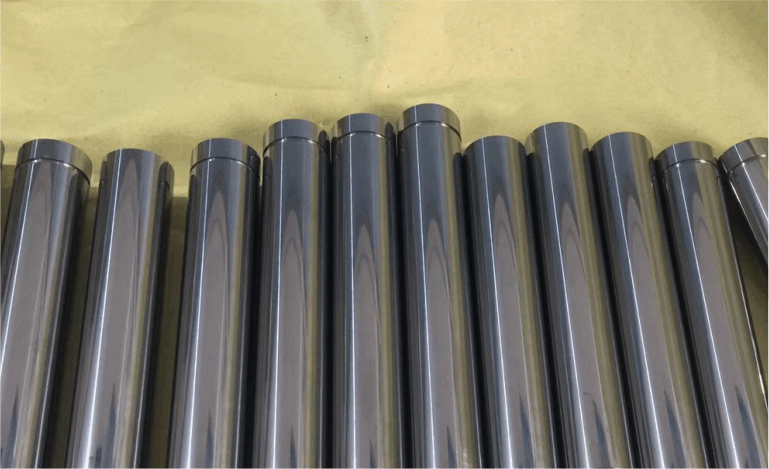

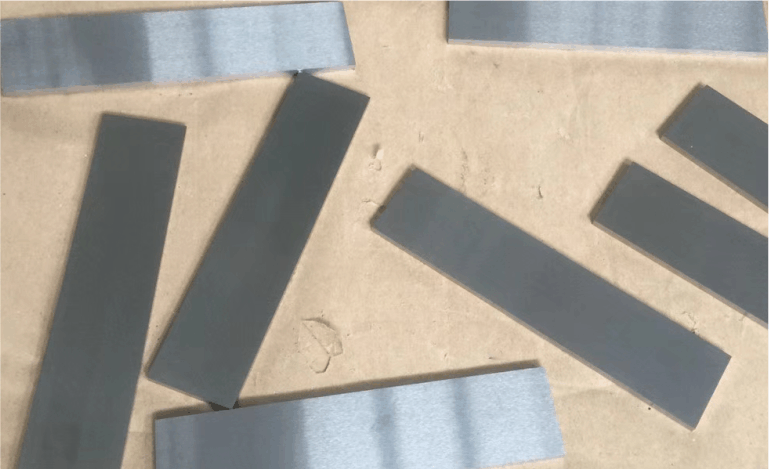

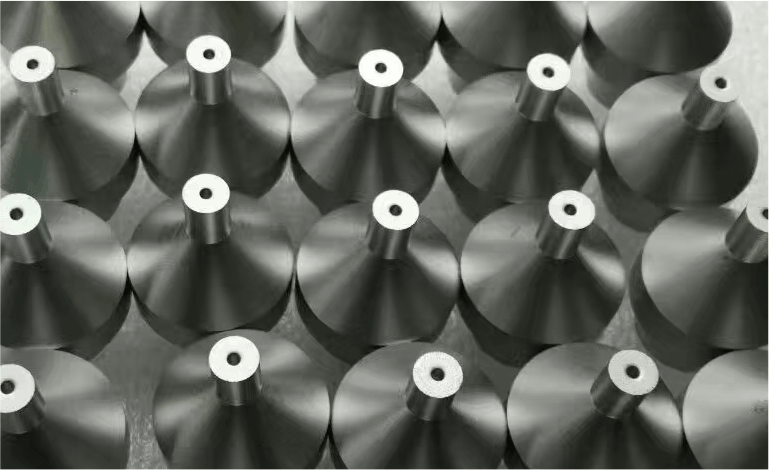

Product Image

STT titanium ceramics

STT titanium ceramics

Performance Characteristics

-

High hardness : hardness up to 6800HV, close to diamond, far higher than cemented carbide and carbon tool steel ;

-

High wear resistance : wear resistance is much higher than that of cemented carbide and ceramics. The wear resistance of cutting materials is generally 50 times that of cemented carbide cutting tools, 30 times that of coated cemented carbide cutting tools and 25 times that of ceramic cutting tools.

-

High thermal stability and high temperature hardness : the heat resistance temperature is as high as 1400-1500 °C, which is almost twice as high as the heat resistance temperature of diamond ( 700-800 °C ) ;

-

Excellent chemical stability : the bonding and diffusion with various materials is much smaller than that of cemented carbide, which can be used to cut steel materials that diamond cannot cut ;

-

Good thermal conductivity : the thermal conductivity is lower than that of diamond but much higher than that of cemented carbide, and the thermal conductivity gradually increases with the increase of temperature, which is beneficial to the temperature of the cutting zone and the diffusion wear of the tool ;

-

Low thermal expansion coefficient : The expansion coefficient of 2 * 10-6 is close to that of quartz glass, which is particularly small in ceramics ;

-

Excellent electrical properties : good high temperature insulation, 2000 °C can reach 103Ω-cm, is a very good high temperature insulation material in ceramics ;

-

Lower friction coefficient : The friction coefficient with different materials is 0.1-0.3. The lower friction coefficient reduces the cutting force, reduces the cutting temperature, and is not easy to produce chips, which is beneficial to improve the surface quality of the processed materials.

Main Usage

-

It is widely used as high temperature, high voltage, insulation and heat dissipation components in aerospace, such as missile microwave window, radar cover, plasma discharge chamber and other insulation and heat-resistant components used in military industry, satellite communication up-going wave tube clamping rod, microwave waveguide insulation heat sink, high temperature wind tunnel plasma insulation sheet ;

-

Metallurgical separation ring for continuous casting steel, flow groove of amorphous iron, release agent for continuous casting aluminum ( various optical glass release agents ), tray for super flat fluorescent screen of float glass picture tube, no adhesion with glass at 1200 °C;

-

Used as tool materials, such as high-speed cutting tools and drills in geological exploration.