Product Structure

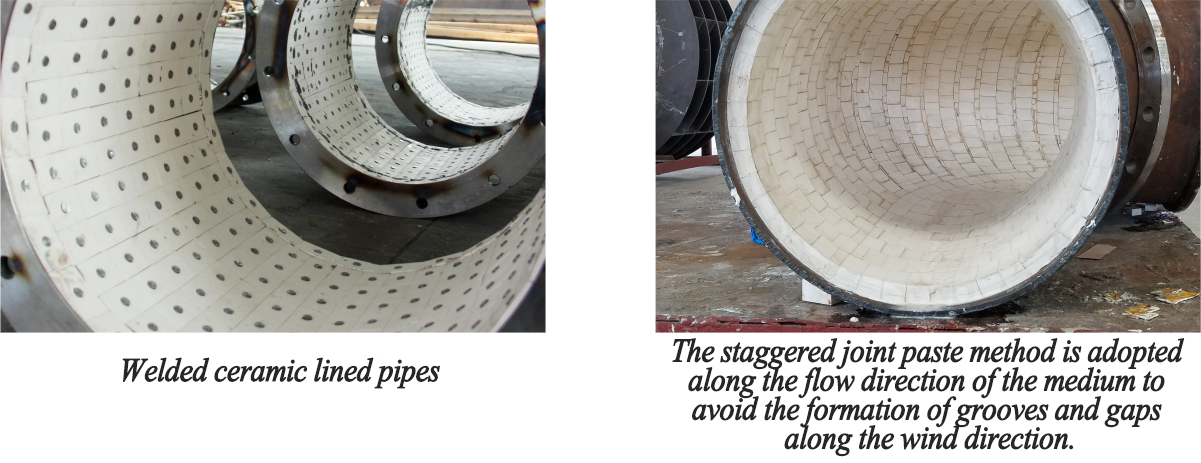

WTP-Pwear-resistant ceramic pipe use paste, welding or dovetail to fix wear-resistant ceramic on the inner wall of the pipe, forming a strong anti abrasion layer. With superior wear resistance it has been widely used in industrial enterprises pneumatic conveying, hydraulic transmission system, especially the erosion site of the elbow, tee, and distributor. It is one of the best channels with its cost effective.Using temperature

Paste: below 300℃ Welding: below 600℃ Dovetail: below 800℃

Suitable medium

Solid particles such as coal powder, ash, slag and slurry, such as coal slurry, slag, and liquid aluminum.

Application

wear-resistant ceramic pipeWidely used in metallurgy, mining, electricity, coal, petrochemical and other industries, gas solid, liquid solid conveyor system, especially for serious damage occurs on the elbow, three links.

Product Features:

Life expectancy of up to 10 years or more

Under the same conditions, it is more than 20 times more wear-resistant than ordinary pipelines ;

Temperature resistance and aging resistance

The suitable material is selected, which can be used for a long time at 700 °C, and the ceramic does not peel off.

low weight

The weight of WTP-P wear-resistant ceramic pipe is just arriving at half of casting stone pipe and approximately 50% of alloy pipe. With advantages of wear and corrosion resistance, the lifetime of WTP-P pipe is outstandingly longer than other wear resistant pipes hereby the cost of assembly and running is largely reduced.

Smooth inner wall

The medium frequency pipe bending machine is bent as a whole, does not produce eddy current, and the material transportation is smooth ;

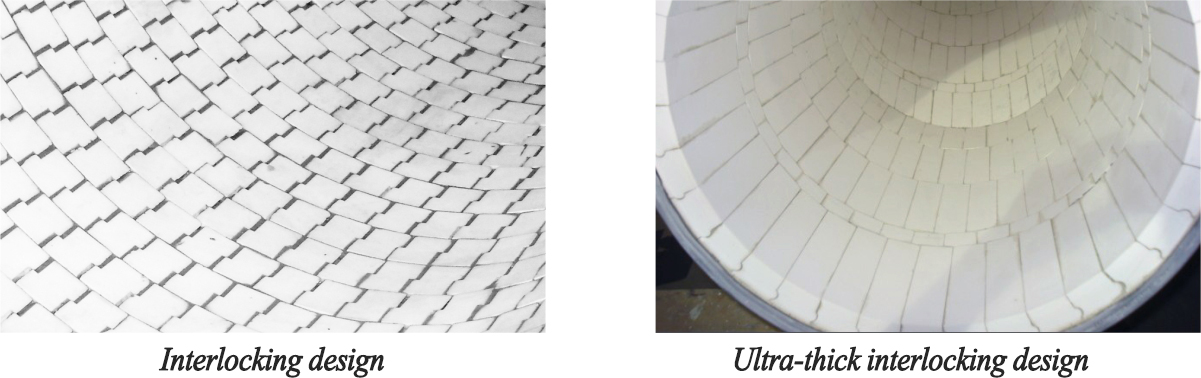

Ceramic staggered installation

The vertical arrangement of ceramics along the wind direction avoids grooves.;

convenient installation

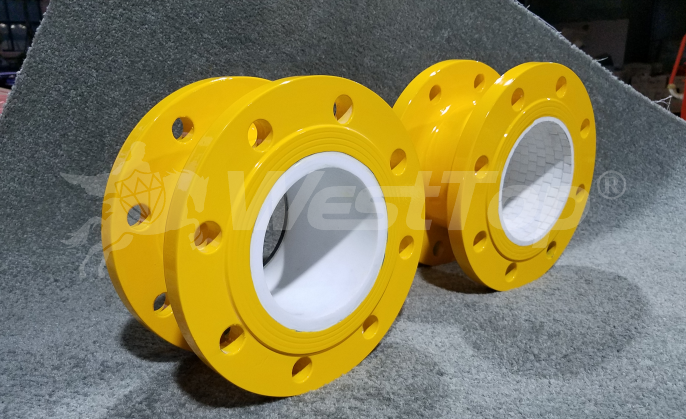

It is easy to carry, save manpower and install more easily and quickly by welding, flange, flexible quick joint and other connection methods.

product image

Wear-resistant ceramic pipe(WTP-P)

Wear-resistant ceramic pipe(WTP-P)

Wear-resistant ceramic pipe(WTP-P)

| The case of hydraulic transportation | Pneumatic conveying case | |||

|---|---|---|---|---|

| line of business | materials | line of business | materials | |

| steelworks | slag | steelworks | Sintering materials, lime, pulverized coal, carbon | |

| boil-plant | slag | boil-plant | Pulverized coal, coke, furnace ash | |

| refuse burning | slag | refuse burning | Industrial or domestic waste | |

| mine | Iron powder, mineral powder, pulverized coal, backfilled tailings | aluminium works | Sintered alumina, bauxite | |

| chemical plant | chemical plant | cement plant | Limestone, clinker, cement | |

| coal mine | Raw coal, slime | Beer factory, malt factory | Hops, malt, rice | |

| Phosphate plant | Phosphoric acid ore | asbestos factory | Sawdust, perlite, stone powder | |

| sewage treatment plant | sludge | smelter | Furnace ash, pulverized coal | |

| Rolling mill, continuous casting plant | Sintering materials, rolling chips | Silicone Plant | Quartz powder, coal |

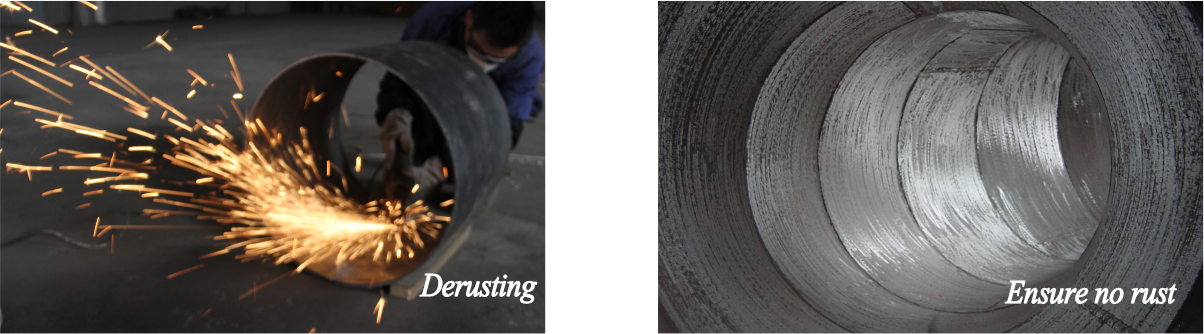

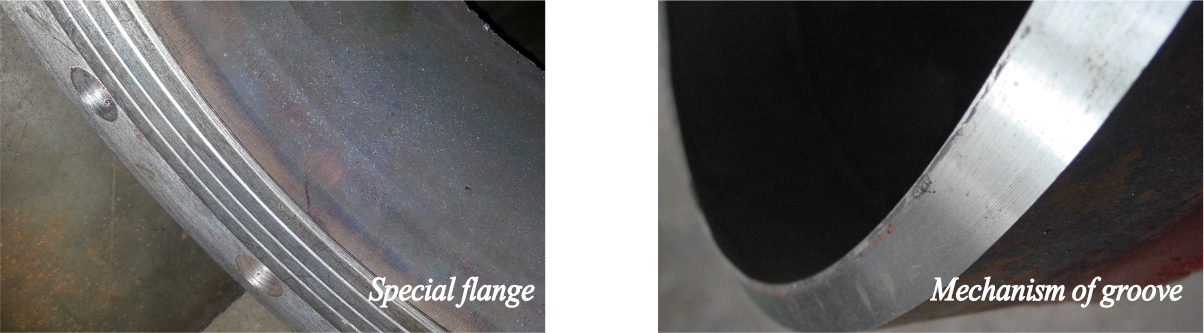

production technology

Pattern selection guide

| item | Composite ceramic pipe | Wear-resistant ceramic pipe | Integral ceramic pipe | Ceramic rubber hose |

|---|---|---|---|---|

| code | WTP-C | WTP-P |

WTP-M |

WTP-CR |

| structural features | Self-propagating centrifugal casting | Ceramics are installed in the pipeline by pasting, welding, swallowtail and so on. |

The ceramic pipe is installed in the steel pipe after sintering. |

Ceramics are embedded in rubber pipes by vulcanization process. |

| Peculiarity | For straight pipe conveying, the cost performance is very high. |

It is used for elbows and tees, and the cost performance is very high. |

It is very good for conveying corrosive slurry. |

It has good flexibility and wear resistance. |

| Applicable medium | Powder / Slurry |

Powder / Slurry |

Powder / Slurry |

Powder / Slurry |

| Outer tube material | 20# |

20#/304 |

20#/304 |

rubber |

| material of inner pipe | Reaction sintering alumina |

STC/ZTA/STA |

STC/ZTA/STA |

STC/ZTA/STA |

| diameter | 630mm | not limited |

300mm |

300mm |

| weight | milder | Very light | lightweight | ultralight |

| Wear resistance ( compared to steel pipe ) | 5 times |

20 times |

20 times |

15 times |

| corrosion resistance | good | good | Very good | good |

| Heat resistance | 700℃ | 800℃ | 1000℃ | 100℃ |

| Pressure resistance | 15MPa |

15MPa |

15MPa |

2.5MPa |