Product briefing

WestTop®STA Alloy ceramic is one of the very tough ceramic materials on the market at present, and it is an excellent combination of hardness and toughness balance.WestTop®STA Alloy ceramics have excellent physical and chemical properties such as high hardness, high strength, high toughness, very high wear resistance and chemical corrosion resistance. Its high impact performance, high bending strength and hardness make it an excellent anti-wear material for high impact parts under harsh working conditions. Its low thermal conductivity makes it an ideal material for thermal insulation of high-voltage mechanical parts. Because of its thermal expansion coefficient close to steel, it has become an ideal substitute for metal mechanical parts in modern design.

WestTop® STA The alloy ceramics are synthesized by mechanical alloying process. The cermet binder added in the powder is composed of high melting point and high hardness metal oxides, carbides, nitrides, carbonitrides, borides, high melting point metals or their alloys, sintering aids and a small amount of rare earth oxides.

WestTop®STA Alloy ceramics have been widely used in ceramics, refractory materials, machinery, electronics, optics, aerospace, biology, chemistry and other fields.

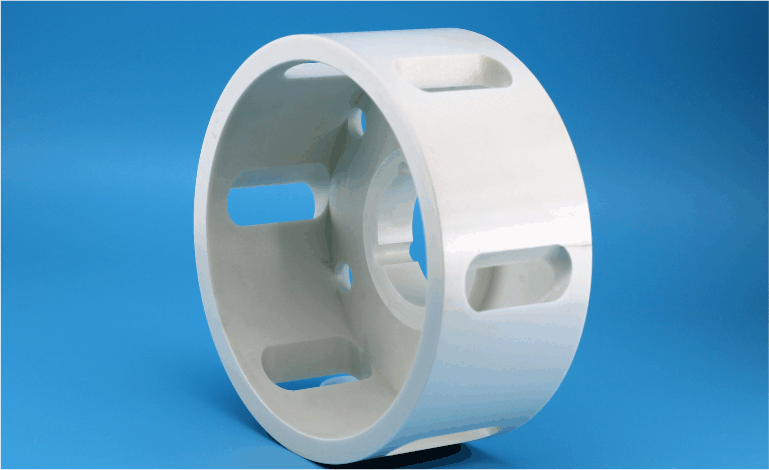

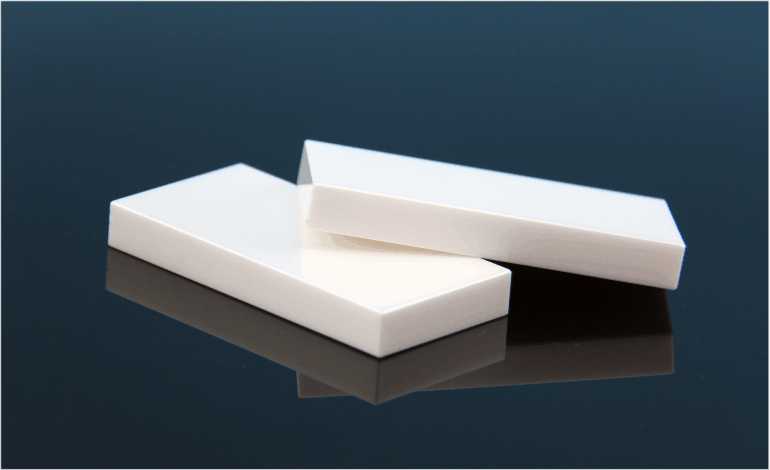

Product image

STA alloy ceramics

Performance Characteristics

-

Ultra-high hardness

-

Good toughness

-

Higher bending resistance

-

Very good wear resistance

-

low density

-

The heat resistance is very good

-

Good insulation performance

-

Very good wear resistance

-

Good corrosion resistance

-

Thermal shock stability is good.

Main Usage

-

It is used in the environment where impact wear is particularly serious in industrial enterprises ;

-

It can be used as grinding body to prevent material pollution, such as grinding of materials in medicine, food, cosmetics and other industries.

-

Produce structural ceramic parts, such as ceramic bearings, ceramic valves, seals, nozzles, plungers, guide wheels, rolls, etc. ;

-

It is used in industries with particularly high corrosion protection requirements, such as coatings, textiles, pigments, printing and dyeing, etc.

-

In terms of functional ceramics, its excellent high temperature resistance can be used as induction heating tube, refractory material and heating element.

-

Produce high-tech daily necessities, such as ceramic tools, jewelry, watch chain, mobile phone shell, etc.