Product Introduction

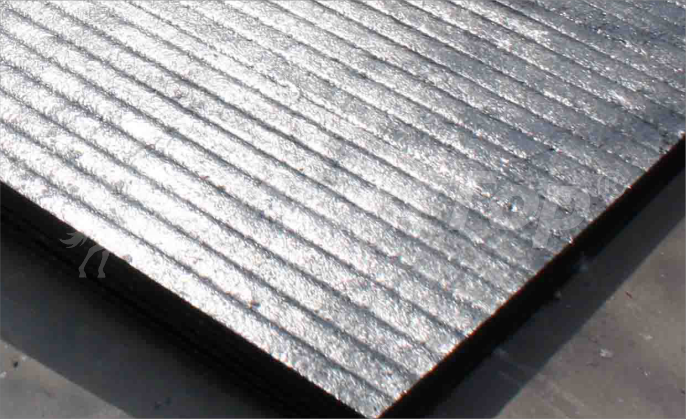

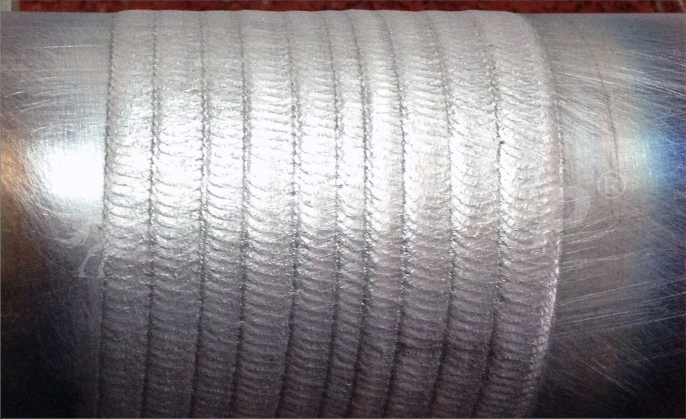

WestTop®SSP alloy wear-resistant composite plate adopts surfacing welding technology to surfacing a layer of alloy wear-resistant layer with high hardness and high wear resistance on the surface of ordinary steel plate or stainless steel plate. It has high wear resistance of working layer and high toughness of substrate, and can realize rolling, welding, plasma cutting and mechanical processing. The wear-resistant layer of WestTop®SSP alloy wear-resistant composite plate is metallurgically bonded with the substrate, the wear-resistant layer has uniform thickness and smooth surface, and there are stress release cracks on the surface of the wear-resistant layer. The cracks only exist in the wear-resistant layer and will not extend to the substrate.The surface of WestTop®SSP alloy wear-resistant composite plate is super wear-resistant steel, and the metallographic structure is martensite + alloy carbide + trace residual austenite. High carbon and high alloy greatly increase the amount of carbides, add multiple hard points, and greatly improve the wear resistance of the material. The inner layer uses low-alloy high-strength steel with a tensile strength of more than 700MPa in the normalizing and tempering state, and an impact toughness of 15J/cm2, which greatly improves the support force of the outer layer and can withstand the pressure of the outer layer during use.

WestTop®SSP has a hardness of up to 63HRC and is still wear-resistant in a high temperature environment of 500-600℃. Its wear resistance is 20-25 times that of low carbon steel, 5-10 times that of stainless steel and high manganese steel, and 1.5 times that of general high carbon and high chromium wear-resistant steel plates.

Performance Characteristics

High wear resistance

The wear-resistant layer and the substrate achieve excellent metallurgical bonding. The carbon content in the chemical composition of the wear-resistant layer is 3%, and the chromium content is as high as 20-40%. The volume fraction of carbides in its metallographic structure is more than 50%. The macro-hardness is HRC55-65, and the micro-hardness of carbides is HV1400-1800, which is much higher than the micro-hardness of quartz in sand and stone HV800-1200, and has excellent resistance to abrasive wear.

Good impact resistance

The substrate of WestTop® SSP alloy wear-resistant composite plate is made of tough materials such as low carbon steel or low alloy steel. The wear-resistant layer resists the wear of the abrasive medium. The substrate bears the load of the medium and can absorb energy during impact, so it has good impact and crack resistance. It can withstand the impact and wear of high-drop hoppers in material conveying systems and other industrial and mining conditions.

Convenient Processing

WestTop® SSP alloy wear-resistant composite plate has good machining performance, and the filament-like stress release cracks on its surface can effectively prevent the high-chromium wear-resistant lining plate from falling off and peeling off during the machining process. It can be made into standard size plates, can be cold-bent inward, and the minimum curvature radius during cold rolling is 600mm. It can be cut by heat sources such as plasma arc and carbon arc, and connected to other workpieces by plug welding, end face welding or back welding bolt connection methods.

High cost performance

WestTop® SSP alloy wear-resistant composite plate can greatly extend the service life of components, greatly reducing maintenance costs and downtime losses. Its cost-effectiveness is about 3-6 times that of ordinary carbon steel.

Typical Applications

Thermal Power

Coal mill cylinder, guide plate, rotating air ring, coal drop pipe, chute, hopper, slag chute, crusher parts, etc.

cement

Vertical mill, chute, impact plate, crusher parts, slag chute, various chassis, vibrating screen, etc.

Steel

Blast furnace chutes, vibrating screens, pellet slides, steelmaking troughs, hot and cold screen plates in sintering plants, silo linings, sliding ramps, feed trucks, etc.

mine

Buckets, crushers, screens, screw conveyors, truck trough liners, hoppers, chutes, crusher parts, covers, wear bars and plates, electric shovels, digging shovels, scrapers, loader buckets, bulldozer buckets, dragline shovels, etc.

port

Grabs, hoppers, chutes, etc. in bulk cargo loading and unloading systems such as iron ore and coal.

Product Images

SSP Alloy composite wear-resistant steel plate

SSP Alloy composite wear-resistant steel plate

SSP Alloy composite wear-resistant steel pipe

SSP Alloy composite wear-resistant surfacing

SSP Alloy composite wear-resistant welding wire

Recommend reading

Comments

Leave a Reply