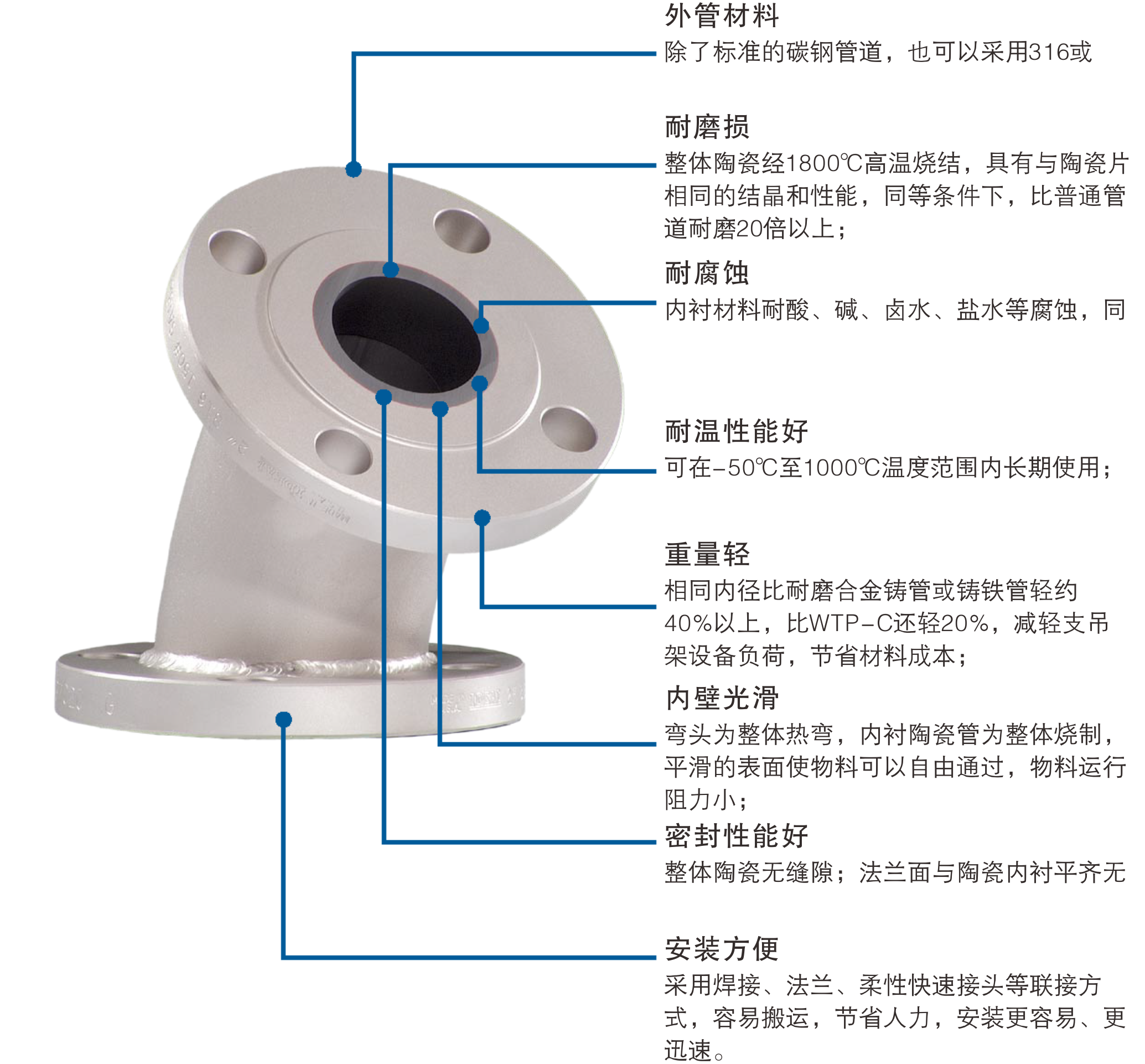

Product Structure

WTP-M Integral wear-resistant ceramic tube. It is composed of prefabricated high-purity ceramic pipes using isostatic pressing technology and then pouring them inside the steel pipes. Different from centrifugally cast ceramic tubes with self-propagation technology, the inner ceramic layer of this product is integrally sintered at a high temperature of 1700°C. Its density, hardness and wear resistance have greatly improved, and its service life is several times longer than the former.Operating Temperature

-50℃~1000℃

Applicable Media

Solid particle powders such as pulverized coal, furnace ash, ore powder, etc.; slurries such as coal slurry, coal slime, slag, aluminum liquid, etc.

Application

Integral wear-resistant ceramic pipeIt is widely used in the wear protection of gas-solid and liquid-solid conveying systems in metallurgy, mining, electricity, coal, petrochemical and other industries, and is particularly suitable for occasions where wear and corrosion are very serious. For example, the desulfurization system of thermal power plants conveys limestone slurry, the mineral processing industry conveys ore slurry, and the chemical industry conveys acid, alkali and other corrosive slurries.

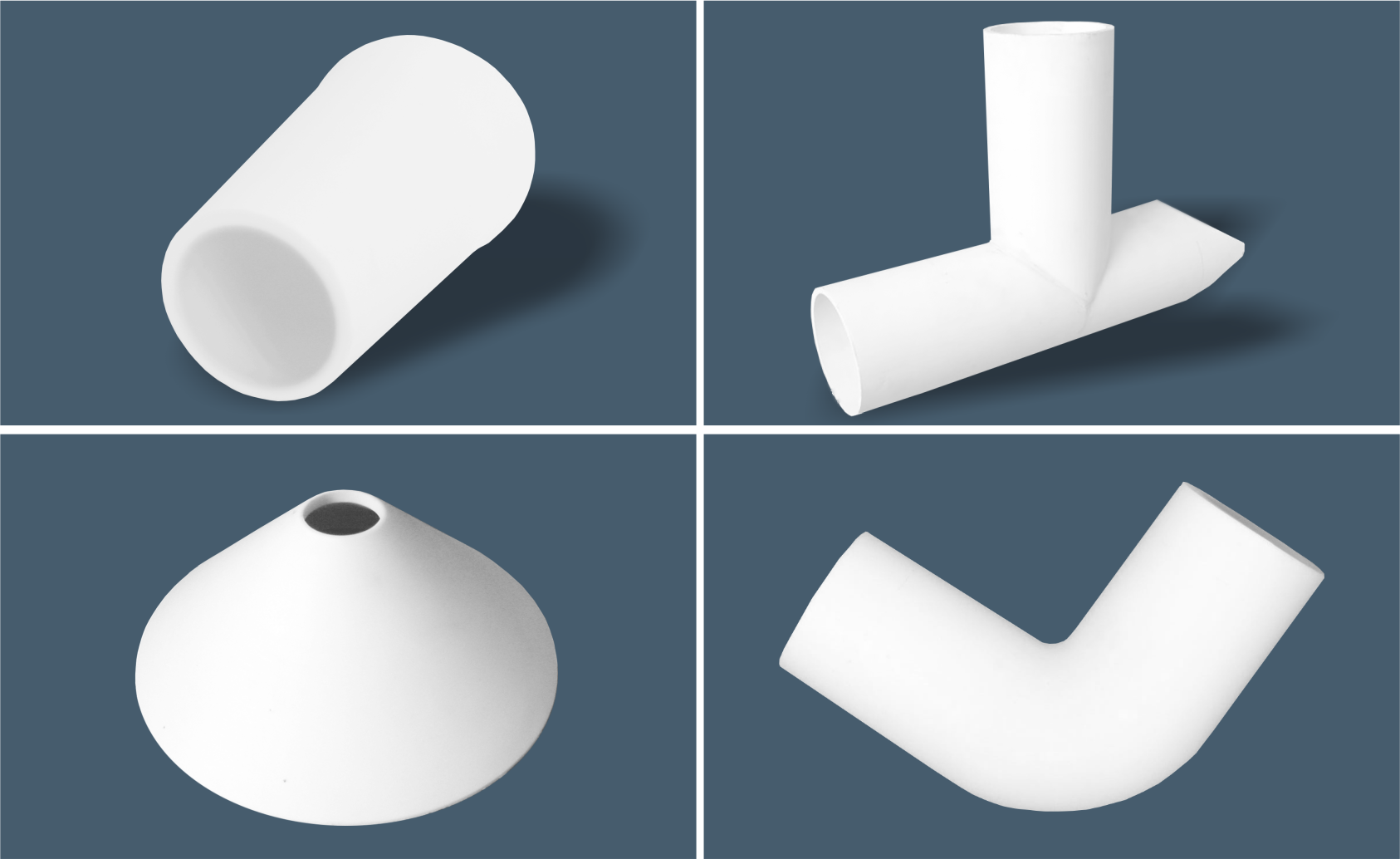

Product Images

Integral wear-resistant ceramic pipe(WTP-M)

Integral wear-resistant ceramic pipe(WTP-M)

| Hydraulic conveying case | Pneumatic conveying case | |||

|---|---|---|---|---|

| Industry | Materials | Industry | Materials | |

| Steel Plant | Slag | Steel Plant | Sintering materials, lime, coal powder, carbon | |

| Thermal Power Plant | Slag | Thermal Power Plant | Pulverized coal, coke, furnace ash | |

| Waste Incineration | Slag | Waste Incineration | Industrial or domestic waste | |

| mine | Iron powder, mineral powder, coal powder, backfill tailings | Aluminum Plant | Sintered alumina, bauxite | |

| Chemical Plant | Chemical Plant | Cement Plant | Limestone, clinker, cement | |

| Coal Mine | Raw coal, coal slime | Breweries, malthouses | Hops, malt, rice | |

| Phosphate Plant | Phosphate rock | Asbestos Factory | Sawdust, perlite, stone powder | |

| Wastewater treatment plants | sludge | Smelter | Furnace ash, coal powder | |

| Steel rolling mills, continuous casting plants | Sintered materials, mill scale | Silicone Plant | Quartz powder, coal |

Selection Guide

| item | Composite ceramic pipe | Wear-resistant ceramic pipe | Integral ceramic pipe | Ceramic rubber hose |

|---|---|---|---|---|

| code | WTP-C | WTP-P |

WTP-M |

WTP-CR |

| structural features | Self-propagating centrifugal casting | Ceramics are installed in the pipeline by pasting, welding, swallowtail and so on. |

The ceramic pipe is installed in the steel pipe after sintering. |

Ceramics are embedded in rubber pipes by vulcanization process. |

| Peculiarity | For straight pipe conveying, the cost performance is very high. |

It is used for elbows and tees, and the cost performance is very high. |

It is very good for conveying corrosive slurry. |

It has good flexibility and wear resistance. |

| Applicable medium | Powder / Slurry |

Powder / Slurry |

Powder / Slurry |

Powder / Slurry |

| Outer tube material | 20# |

20#/304 |

20#/304 |

rubber |

| material of inner pipe | Reaction sintering alumina |

STC/ZTA/STA |

STC/ZTA/STA |

STC/ZTA/STA |

| diameter | 630mm | not limited |

300mm |

300mm |

| weight | milder | Very light | lightweight | ultralight |

| Wear resistance ( compared to steel pipe ) | 5 times |

20 times |

20 times |

15 times |

| corrosion resistance | good | good | Very good | good |

| Heat resistance | 700℃ | 800℃ | 1000℃ | 100℃ |

| Pressure resistance | 15MPa |

15MPa |

15MPa |

2.5MPa |

Recommend reading

Comments

Leave a Reply