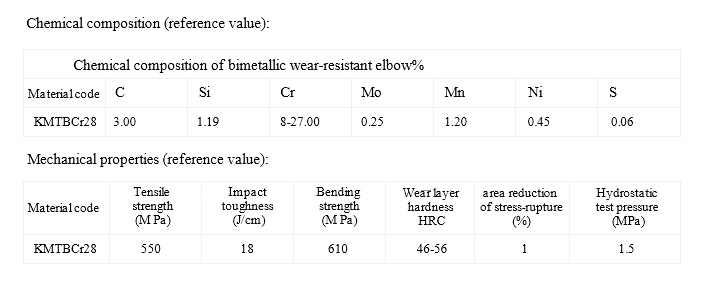

Generally speaking, bimetallic wear-resistant composite steel pipe is also called bimetallic wear-resistant composite pipe, bimetallic composite wear-resistant steel pipe or bimetallic wear-resistant steel pipe. It generally refers to KMTBCr28 bimetallic wear-resistant composite steel pipe, which is different from rare earth alloy wear-resistant pipe, high chromium cast iron and other single metal pipes. The hardness of a metal will not directly affect the welding performance. Although the hardness of these two metals is not very low, both of which are above HRC40, although they can be welded, the performance is still not ideal, and cracking will occur during the welding process. Therefore, how to find materials with good wear resistance, good welding performance and excellent impact resistance in many metals ? Only by finding the balance of these properties, using a variety of metals to make a bimetallic wear-resistant composite steel pipe can achieve a balance between high wear resistance, weldability and impact resistance.

The production process of bimetallic wear-resistant composite pipe is mainly divided into two kinds. One is the lost foam vacuum suction casting composite process. The vacuum suction casting composite process is one of the best metal composite processes in the world. It belongs to semi-precision casting technology. Compared with sand casting, the surface accuracy is greatly improved. The phenomenon of sand washing and sand inclusion occurs, and there will be no defects such as holes due to vacuum casting. Due to the high dimensional accuracy of the mold manufacturing process, the thickness of the wear-resistant composite layer of the cast-plastic composite wear-resistant pipe is uniform, which avoids the uneven wall thickness of the product caused by molding. General casting method due to demoulding and repair process. Its organization is unified and its performance is stable. At the same time, the process can be composed of straight pipes and shaped pipes of any size and diameter, and can be used to manufacture pipes and eccentric pipes with reduced overall composite materials for bent pipes, tees, cross-shaped, conical pipes, and diameter pipes with inconsistent wall thickness. Reduce operating resistance and reduce the operating cost of material transportation.The other is the inner wall material casting. KMTBCr28, as the inner wall of the bimetallic wear-resistant composite pipe, has stable quality and good comprehensive performance. Adding rare earth elements to improve the quality of steel alloys, refine grains and form a protective film on the surface ; the addition of molybdenum makes the alloy have anti-oxidation effect at high temperature and increases the service life. The addition of boron carbide can control the hardness in the range of HRC45 ~ 65, and solve the contradiction between the hardness and weldability of wear-resistant steel, and has high wear resistance. On the basis of traditional ingredients, rare metal and boron carbide hardener are added, which greatly increases the hardness and fatigue resistance of traditional products, and makes its wear resistance better than other products.

As a metal pipe that achieves a balance between high wear resistance, weldability and impact resistance, the bimetallic composite wear-resistant steel pipe has excellent physical and chemical properties. On the basis of the traditional material process, some rare metals and boron carbide hardener are added, which greatly improves its hardness and fatigue resistance. The wear resistance of the bimetallic wear-resistant steel pipe is better than that of other single metal pipes.