Product Structure

Westtop ceramic-rubber composite type(WT-R)uses rubber vulcanization technology to embed special ceramics in special rubber to form a ceramic-rubber composite lining,forming a strong and cushioning wear-resistant layer. Rubber effectively absorbs impact loads, while ceramic protects the surface.In addition, it can be vulcanized with a steel plate with countersunk bolts for quick installation and replacement.

Practice has proved that WT-R has excellent performance in material conveying systems with heavy workloads and harsh working conditions.

Optional Materials

ceramics:STC wear-resistant ceramics/ZTA Zirconia toughened alumina ceramics/STA alloy ceramic

Adhesive: Ordinary rubber/Heat-resistant rubber (150°C)/Cold-resistant rubber (-50°C)/Flame-retardant rubber

Operating Temperature

-50℃ to 150℃

Applicable Media

bulk materials such as coal, coke, slag, cement clinker, limestone, etc.

Application

Suitable for chutes and hoppers in low temperature bulk material conveying systems. Such as coal falling pipe, coal falling bucket, vibrating screen, etc.

Common Specifications

16/20/24/30/62mm

Performance Characteristics

Super Wear-resistant

extend equipment life by more than 10 times;

Good Impact Resistance

Ceramic is a toughening formula, and rubber can play a good role in buffering and absorbing energy. It can easily handle large particles under 200mm;

Anti-fall

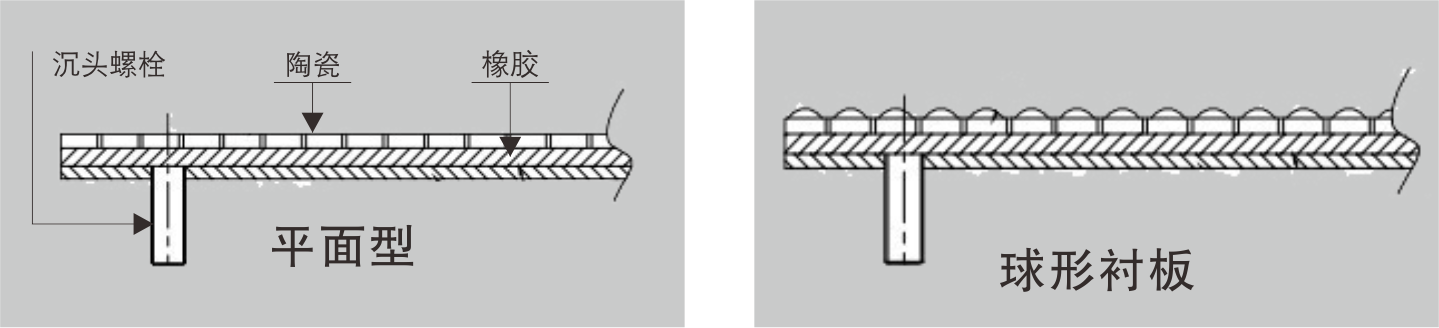

The ceramic rubber steel plate is vulcanized in one piece, and the combination is very strong; each lining plate has countersunk head bolts passing through the bottom steel plate, and is firmly welded, providing double insurance;

Easy Maintenance

The lining plate is equipped with countersunk bolts and is more than 60% lighter than the wear-resistant steel plate, making installation and replacement very convenient.

Liner Structure

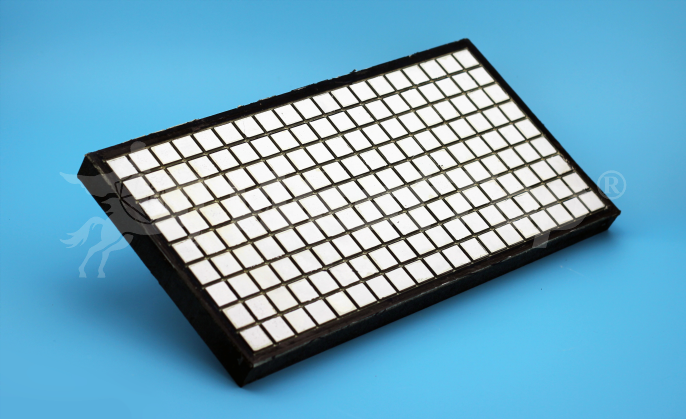

Product Images

Ceramic rubber composite wear-resistant ceramic liner(WT-R)

Ceramic rubber composite wear-resistant ceramic liner(WT-R)

Selection Principle Of Wear-resistant Ceramics

| Item | Code | Service Temperature(℃) | Applicable Medium | Material Pellets(mm) | Range Of Application |

|---|---|---|---|---|---|

| Paste Type | WT-P | 300 |

Powder / Slurry |

≤3 |

Pneumatic conveying powder or slurry below 300°C |

| Welded | WT-W | 300-800 |

Powder / Slurry |

≤10 |

Pneumatic conveying of powder or slurry of larger particles below 800 °C |

| Swallow-tailed | WT-S |

≤800 |

Powder / Slurry |

≤200 |

Conveying large particle powder or high-speed rotating equipment below 800 °C |

| Impact resistant type | WT-T |

≤800 |

Particle / slurry |

≤200 |

Bulk material conveying system below 800 °C, especially suitable for the mixture of hard bulk material and powder material |

| Ceramic rubber composite | WT-R |

-50~150 |

Particles / slurry |

≤200 |

Bulk material conveying system below 150 °C, especially suitable for pure soft bulk material conveying, can resist large impact |

| Rapid ceramic repair agent | CRA |

-30~200 |

slurry |

≤10 |

Especially suitable for corrosive slurry conveying equipment lining. |