The development of surface roughness standard is closely related to the development of industrial production technology. It has gone through two stages from qualitative evaluation to quantitative evaluation. The effect of surface roughness on the surface properties of mechanical parts has attracted much attention since 1918. In the design of aircraft and aircraft engines, because less material is required to obtain greater strength, the influence of tool marks and scratches on the fatigue strength of the machined surface is studied. However, due to the difficulty of measurement, there was no requirement for quantitative evaluation at that time, which could only be determined by vision. In the 1920 s and 1930 s, many industrial countries in the world widely used the combination of triangular symbols ( ▽ ) to represent machined surfaces with different precisions.

In order to study the influence of surface roughness on the performance of parts and measure the micro-surface roughness, from the late 1920 s to the 1930 s, some experts designed and manufactured contour recorders and profilometers. At the same time, an optical cutting microscope and an interference microscope were developed to measure the surface micro-roughness by optical methods, which created conditions for quantitative evaluation of surface roughness by numerical methods. Since the 1930 s, people have studied the quantitative evaluation parameters of surface roughness.

With the development of industry, the need of opening to the outside world and technical cooperation, the research and standardization of surface roughness have been paid more and more attention by science and technology and industry. In order to quickly change the disunity of terms and concepts in domestic surface roughness and realize the role of international unity, GB3505-1983 ‘ surface roughness term surface and its parameters ‘ are formulated according to the relevant international standards ( ISO ) of the International Organization for Standardization ( ISO ). GB 3505 clearly defines the terms related to surface roughness and its parameters, including three parts, a total of 27 parameter terms :

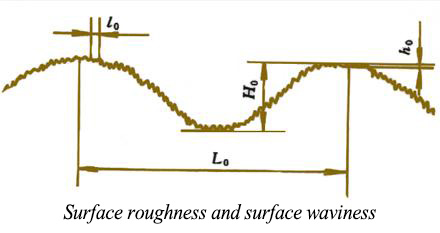

- Terminology of surface roughness parameters related to micro-roughness height characteristics. The commonly defined terms are : contour arithmetic mean deviation Ra, contour root mean square deviation RQ, contour height Ry and micro-inhomogeneity ten-point height Rz.

- The surface roughness parameter term related to the micro-roughness spacing characteristic has nine parameters, such as the average spacing Sm, the peak density D, the root mean square wavelength LQ and the single peak average distance S.

- There are five parameters related to the terms of surface roughness parameters and micro-roughness shape characteristics : profile deviation Sk, profile root mean square slope DQ and profile support length ratio tp.