PRODUCT BRIEFING

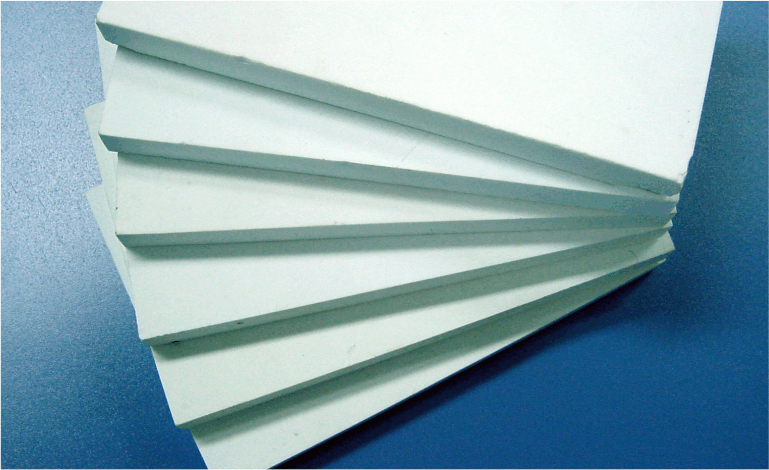

The main component of WestTop® STC wear-resistant ceramics is high-purity alumina. Due to the excellent performance and good cost-effectiveness of alumina, it is currently a widely used ceramic material. It is used in places that require high wear resistance, good corrosion resistance and pressure resistance. Due to its insulating properties, it is also often used in electronic products.Westtop improves the quality of ceramics through four processes :

1. The raw materials use high-purity phase αAL2O3 and crystal growth inhibitors, and use zirconia with excellent toughness as a toughening and modifying component, thereby effectively improving the wear resistance and impact resistance of alumina products.

2. The powder adopts a very advanced powder preparation process, and the granulated powder produced is evenly distributed and has good fluidity.

3. Using 200 tons of dry pressing molding, the pressed blank has a high density and is easy to sinter.

4. Strict sintering process and precise computer temperature control system reduce the generation of internal pores, and the sintered products are dense and non-deformed.

performance characteristics

-

Ultra-high hardness

-

Very good wear resistance

-

low density

-

The heat resistance is very good

-

Good insulation performance

-

Good corrosion resistance

-

Thermal shock stability is good.

main usage

-

Used in various fields of anti-wear, mainly used for industrial enterprises material conveying and preparation system related equipment anti-wear ;

-

For high temperature environment, such as crucible, refractory furnace tube, thermocouple, laser tube, etc. ;

-

For anti-corrosion environment, such as acid and alkali environment material conveying system equipment corrosion ;

-

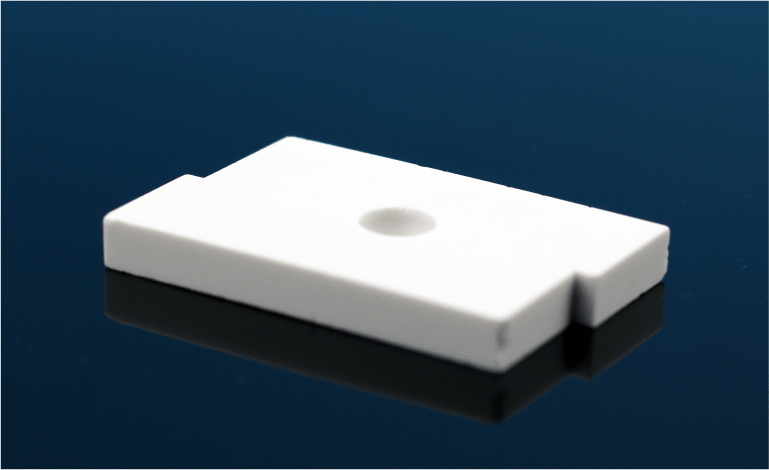

Producing electronic ceramics, such as circuit boards, substrates, vacuum devices, etc. ;

-

Produce structural ceramic parts, such as ceramic bearings, seals, water valve plates, wear-resistant parts of textile machines, automobile spark plugs, metal wire drawing dies, etc. ;

-

Used for bulletproof purposes, such as ceramic armored vehicles, bulletproof sheets, etc.