Product Introduction

Ceramic pulley lagging is an important component in the belt conveyor system. The pulley lagging can effectively improve the operating conditions of the conveyor system, protect the metal roller from wear, prevent the slippage of the conveyor belt, and enable the roller and the belt to operate synchronously, thereby ensuring the efficient and effective operation of the belt. Large-capacity operations. The pulley lagging can also effectively prevent the sliding friction between the roller and the belt, reduce the material adhesion on the roller surface, and thereby reduce the belt deviation and wear.Traditional pulley lagging uses a hot vulcanization process to wrap rubber on the roller, but the defects are obvious in practical applications:

■ The vulcanization pressure is low, the product has poor density and wear resistance;

■ Hot vulcanized casting rubber is vulcanized under low pressure, and there will be a large amount of sulfur in the formula, and rubber containing too much sulfur will gradually harden in the air;

■ The connection between the hot cast rubber and the roller is achieved by a transition layer, but the connection strength between the transition layer and the metal is not high (3-10N/MM), and cracks between the transition layer and the metal often occur;

■ Due to the high hardness of the rubber, the hot-cast lagging has poor self-cleaning function on the roller surface;

■ Under harsh working conditions, the surface texture of ordinary pulley lagging is easy to wear, causing the belt to slip and deviate.

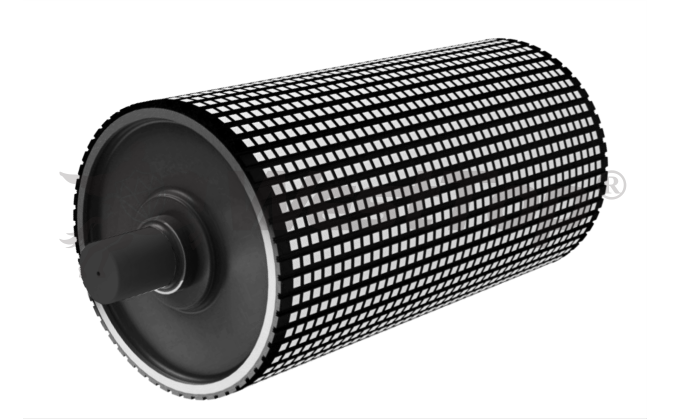

As a pulley lagging manufacturer, westtop produces WTB ceramic pulley lagging by vulcanizing ceramics with raised points on the surface into special rubber, and then using cold vulcanization technology to vulcanize it on the surface of the roller to replace traditional rubber.

Westtop is one of the manufacturers of pulley lagging that insists on using high-quality rubber and ceramic to make pulley lagging. The company’s embedded design and cold vulcanization technology make the WTB ceramic pulley lagging produced by Xituo have super wear resistance and anti-slip performance. The high-performance cold vulcanization adhesive imported from Germany ensures the reliability of the lining. Advanced technology, reliable technology, fast and convenient construction. On-site construction reduces the intensity of workers’ disassembly and assembly, avoids safety hazards, saves enterprise downtime, and improves maintenance efficiency.

Applicable Scope

■Suitable for cleaning non-working surfaces during return trip;■Satisfies bandwidth: B600—2400mm

■Suitable for conveyor belts with vulcanized joints and mechanical joints

■Suitable for belt speed within 4.5m/s, working environment temperature range -40℃ to +80℃

■It can be used in oil-resistant, corrosion-resistant and other working environments.

■Only suitable for conveyor belts operating in one direction.

Features and Benefits

Anti-SlipThe ceramic surface has uniform spherical protrusions, and the friction coefficient is three times that of traditional rubber pulley lagging. Thousands of protrusions can generate traction when the back side of the conveyor belt passes, preventing the conveyor belt from slipping and deviating, and improving conveying efficiency;

Anti-Deviation

The main reason for the belt deviation of the traditional rubber pulley lagging is the wear of the rubber coating and material accumulation. There is almost no wear on the surface of WTB, and the materials that occasionally enter will be discharged through the groove, without causing material accumulation problems;

Protective Belt

1. The convex point has no angular design, and there will be no problem of wear on the conveyor belt caused by the sharp edges of the convex particles common in other ceramic lagging products;

2. There is no relative sliding between the roller and the belt, which further protects the belt from wear;

3. Under the same load, the tension of the belt can be reduced and the service life of the belt can be extended;

No accumulation of material on the surface

Each ceramic rubber plate has grooves at certain intervals, which can allow foreign matter (dust, soil) on the drum to be discharged along the grooves, making use of the drum’s self-cleaning function, which is particularly suitable for humid working environments;

Long lifespan

The service life is more than 5 times that of ordinary rubber rollers;

Easily handle harsh working conditions

In harsh conditions such as slippery, muddy, long-distance transportation, etc., WTB shows even better performance;

Shock resistance

The elasticity of the bottom rubber can provide good impact resistance;

Quick and easy installation

There is no need to remove the roller from the conveyor, which reduces the cost of disassembly and transportation of the roller, saves time, and eliminates labor intensity and safety hazards for workers to a certain extent. At the same time, there is no need to damage other parts of the belt conveyor when removing and installing the roller.

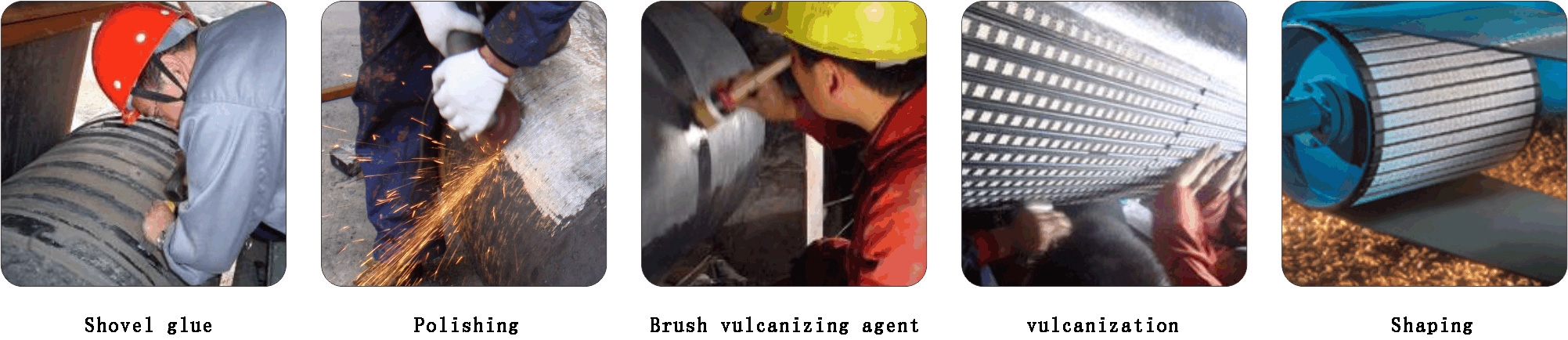

Construction Technology

Product performance indicators

| Project | Ceramic hardness (Vickers) | Rubber elongation | Rubber hardness | Ceramic rubber tensile strength | Ceramic pulley lagging heat resistance |

|---|---|---|---|---|---|

| Indicators | 1800 | 400% |

60±5(shoreA) |

150kg/cm2 |

100℃ |

Friction coefficient under different working conditions

| Working conditions | Steel (without pulley lagging) | pulley lagging | Ceramic Lagging |

|---|---|---|---|

| Dry | 0.35-0.4 | 0.4-0.45 |

0.75-0.85 |

| Wet | 0.1-0.15 | 0.33-0.38 |

0.5-0.8 |

| Muddy | 0.1-0.15 |

0.22-0.30 |

0.45-0.55 |

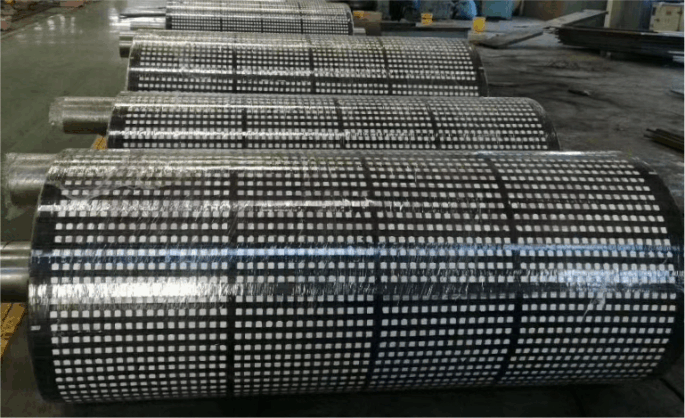

Product Images

Ceramic pulley lagging(WTB)

Ceramic pulley lagging(WTB)

Ceramic pulley lagging(WTB)

Ceramic pulley lagging(WTB)

Ceramic pulley lagging(WTB)

Application

It is suitable for very harsh conditions such as high wear, easy slip, and wet materials or surrounding environment, especially suitable for steel cable conveyor belts and high-speed, high-tension conveyor belts.

Roller form

Driving roller, redirecting roller, passive pulley

Drum diameter:300-1800mm

Operating Temperature:≤100℃