Product Structure

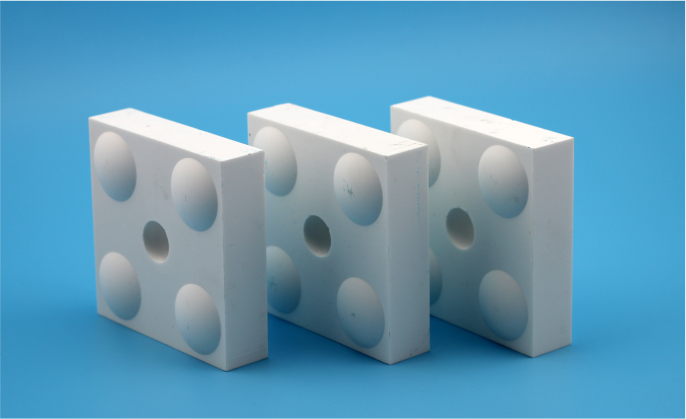

The ceramic has a unique toughening formula, and the ceramic is designed into a spherical shape to effectively break down the impact of incoming materials. Combined with the advanced stud welding process, it can ensure to a greater extent that the ceramic will not break or fall off under the impact of large materials.Optional Materials

ceramics:STC wear-resistant ceramics/ZTA Zirconia Toughened Alumina Ceramics/STA Alloy Ceramic

Viscose:WTV-200/WTV-300/WTV-500/WTHV-800

Operating Temperature

Below 800℃

Applicable Media

Coal, coke, ore, cement clinker, sintered ore, etc. with material particles no larger than 200mm.

Application

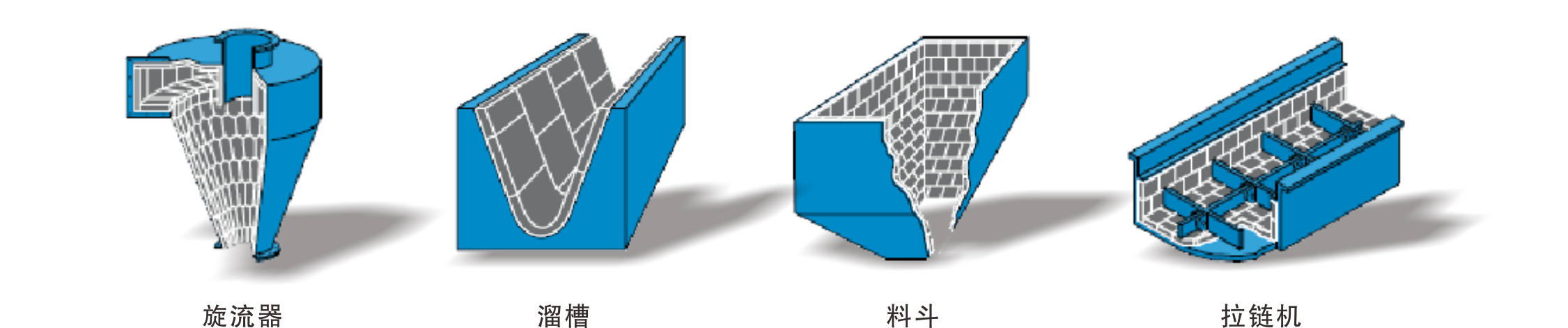

It is suitable for wear protection of material conveying chutes, hoppers and other equipment in thermal power, steel, cement, coal, ports, mining, chemical and other industries.

Common Specifications

thickness:20/25/30/50/70mm

Performance Characteristics

Super wear-resistant

Vickers hardness is as high as 1800, which can extend the service life of the equipment by more than 15 times;

Good toughness, impact resistance

Nanostructure and whisker toughening technology give Westtop ceramics outstanding toughness, even in very harsh working conditions, it can easily cope with;

Stud welding, not easy to fall off

Westtop uses advanced imported stud welding technology and strong adhesive,greater guaranteeceramics are not easy to fall off under high impact conditions.

Not easy to stick to materials

The ceramic surface is smooth, does not generate static electricity with the material, and is not easy to stick to the material.

Product Images

Impact-resistant wear-resistant ceramic lining(WT-T)

Impact-resistant wear-resistant ceramic lining(WT-T)

Impact-resistant wear-resistant ceramic lining (WT-T) not afraid of heavy impact

Typical Applications

| Item | Code | Service Temperature(℃) | Applicable Medium | Material Pellets(mm) | Range Of Application |

|---|---|---|---|---|---|

| Paste Type | WT-P | 300 |

Powder / Slurry |

≤3 |

Pneumatic conveying powder or slurry below 300°C |

| Welded | WT-W | 300-800 |

Powder / Slurry |

≤10 |

Pneumatic conveying of powder or slurry of larger particles below 800 °C |

| Swallow-tailed | WT-S |

≤800 |

Powder / Slurry |

≤200 |

Conveying large particle powder or high-speed rotating equipment below 800 °C |

| Impact resistant type | WT-T |

≤800 |

Particle / slurry |

≤200 |

Bulk material conveying system below 800 °C, especially suitable for the mixture of hard bulk material and powder material |

| Ceramic rubber composite | WT-R |

-50~150 |

Particles / slurry |

≤200 |

Bulk material conveying system below 150 °C, especially suitable for pure soft bulk material conveying, can resist large impact |

| Rapid ceramic repair agent | CRA |

-30~200 |

slurry |

≤10 |

Especially suitable for corrosive slurry conveying equipment lining. |