Product Structure

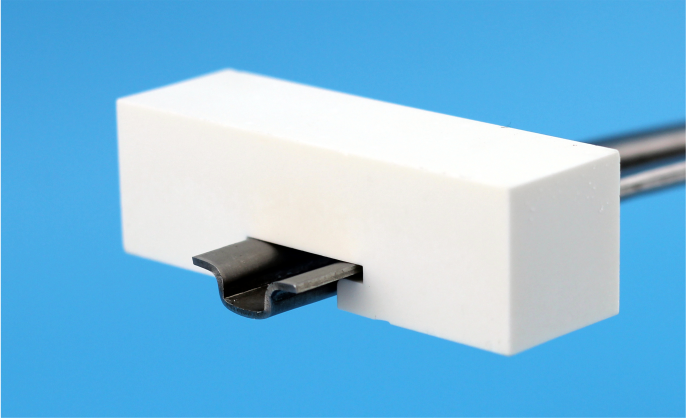

Dovetail wear-resistant ceramics are installed on the equipment, which wrap the dovetails. The steel dovetail strips will not be eroded by materials. An independent dovetail structure can ensure the reliability of equipment operation to a greater extent.Optional Materials

Ceramic:STCwear-resistant ceramics/ZTA Zirconia Toughened Alumina Ceramics

Viscose:WTV-200/WTV-300/WTV-500/WTHV-800

Operating Temperature

Below 800℃

Suitable Medium

Solid powder particles such as coal powder, limestone, clinker, cement, etc., slurries such as ash, slag, gypsum, limestone, etc.

Application

Suitable for wear protection of equipment operating at high temperatures or dynamically. Such as fan impellers, burners, air pre-heaters, etc.

Common Specifications

Thickness: 8/10/20/25/30mm

Performance Characteristics

Super wear-resistant

Wear resistance is 20 times that of ordinary carbon steel;

Very strong

The dovetail structure is one of the most solid fixing methods for wear-resistant ceramic applications.;

High temperature resistance

The use of dovetail strips with better heat resistance can give full play to the advantages of the dovetail structure. Combined with the WTVH series adhesive from westtop, it has an ultra-high temperature resistance of 800°C and meets the needs of ultra-high temperature working conditions.

Good impact resistance

By using westtop’s wear-resistant materials with better toughness and thickening the thickness of the ceramic material, satisfactory impact resistance can be obtained and used on high-temperature and high-impact equipment, such as coke hoppers and slag in steel plants.

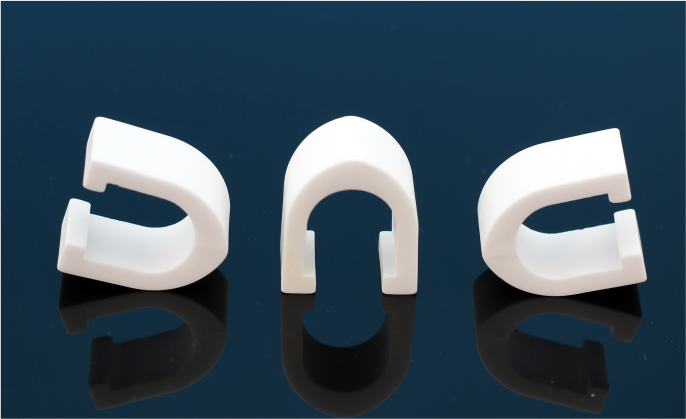

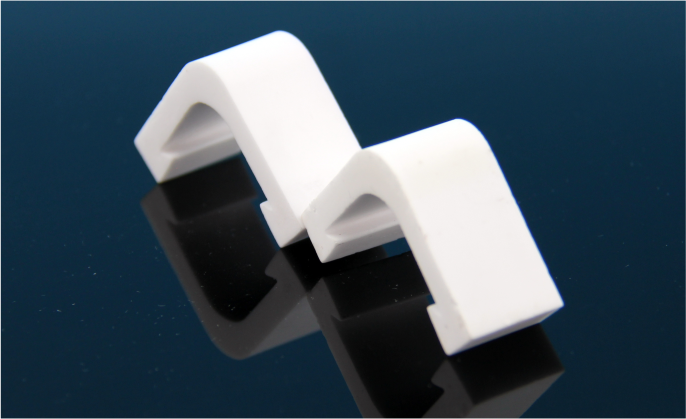

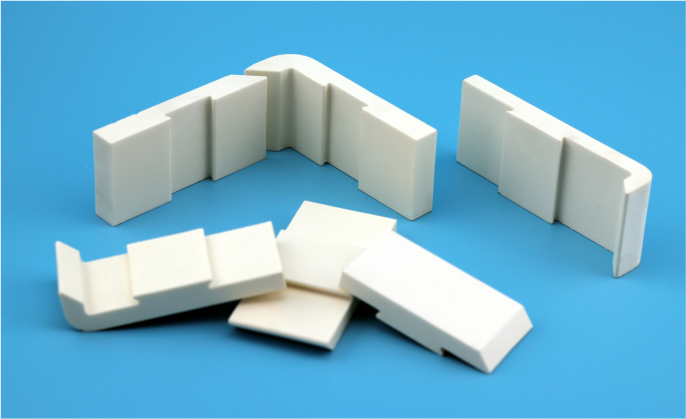

Product Images

Dovetail wear-resistant ceramic lining(WT-S)

Dovetail wear-resistant ceramic lining(WT-S)

Dovetail wear-resistant ceramic lining(WT-S)

| Item | Code | Service Temperature(℃) | Applicable Medium | Material Pellets(mm) | Range Of Application |

|---|---|---|---|---|---|

| Paste Type | WT-P | 300 |

Powder / Slurry |

≤3 |

Pneumatic conveying powder or slurry below 300°C |

| Welded | WT-W | 300-800 |

Powder / Slurry |

≤10 |

Pneumatic conveying of powder or slurry of larger particles below 800 °C |

| Swallow-tailed | WT-S |

≤800 |

Powder / Slurry |

≤200 |

Conveying large particle powder or high-speed rotating equipment below 800 °C |

| Impact resistant type | WT-T |

≤800 |

Particle / slurry |

≤200 |

Bulk material conveying system below 800 °C, especially suitable for the mixture of hard bulk material and powder material |

| Ceramic rubber composite | WT-R |

-50~150 |

Particles / slurry |

≤200 |

Bulk material conveying system below 150 °C, especially suitable for pure soft bulk material conveying, can resist large impact |

| Rapid ceramic repair agent | CRA |

-30~200 |

slurry |

≤10 |

Especially suitable for corrosive slurry conveying equipment lining. |